Getting Started

Interface Basics

Printers and Scales

Shipping

Order Processing

Order Allocation

Order Processing Loop

Packing Solutions

Backorders

Ready to Ship

"Unable to Process" Order status

Address Validation and Classification

Packaging Features

Orders

Custom Fields for Orders

Reference Numbers

Other Shipping Options

Packing Instructions

Shipping Accounts

External Shipping Methods

Third Party Billing

Manifest Couriers

Packing Slip Design

Service Levels and Target Ship Dates

Outbound SSCC Barcodes

International Shipping

Tracking Numbers for Offline Shipments

Serial Number Tracking

Custom Fields for Shipments

Receiving

Catalog

Bill of Materials/Work Orders

Bill of Materials

Bill of Materials - Quantity-types

Work Orders

Import Bill of Materials

Virtual Inventory

Regulations

Products

Product Attributes

Lots/Expirations Tracking

Product Velocity

Import Products

Operations

Warehouse

Picking Classes

Picking Batches

Bulk Fulfill Orders

Put-Aways

Manifests (Loading)

License Plates

Time Tracking for Administrators

Time Tracking for Staff

Relocations

Import Locations, Lots and Inventory

Assets

Batching Presets

Rating

Rate Shopping

Rating Maps

Rate Groups and Plans

Fee Schedules and Adjustments

Virtual Shipping Methods

System

Configuration

Merchants and Brands

Warehouses

User Management

User Roles

User Groups

Login via Badge

Protected Customer Data

Enumerations

Technical Contact

Integrations

Shopify

Integrations Overview

Amazon Merchant Fulfillment

Amazon Selling Partner

CartRover

EasyPost

eHub

External Shipping Method API

Freight Club

Magento 1 / OpenMage

Merchant API Users and Roles

SPS Commerce

ShipStream Plugin Fostering Program

Webhooks

Global Integrations

Magento 2 / Adobe Commerce

WooCommerce

UPS

Scripting

Scripting Basics

Before Create Order Scripts

Before Create Order scripts Cookbook

Preprocess Packing Solution Scripts

Ready to Ship Time Scripts

Picking Class Shipment Matching Scripts

FAQ

How-To: FedEx Production Key Certification

How-To: Brand-Specific Shipping Account

Pattern and Replacement RegEx

ShipStream's Subprocessors

ISO Alpha-2 Country Codes

Printer Troubleshooting

ShipStream Flow

Release Notes

ShipStream Releases

Version 2025.7

Version 2025.6

Version 2025.5

Version 2025.4

Version 2025.3

Version 2025.2

Version 2025.1

Applicable Quantity Migration Guide

Version 2025.0

Revamped Delivery Processing

Version 2024.6

Version 2024.5

Version 2024.4

Version 2024.3

Version 2024.2

Version 2024.1

Version 2024.0

Version 2023.2

Version 2023.1

Version 2023.0

Package Tracking API Migration Guide (2023.0)

Version 2022.2

Version 2022.1

Version 2022.0

Version 2021.6

Version 2021.5

Version 2021.4

Version 2021.3

Version 2021.2

Version 2021.1

Version 2021.0

Version 2020.2

Version 2020.1

Version 2020.0

Version 2019.9

Version 2019.8.1

Version 2019.8

Version 2019.7

Version 2019.6

Version 2019.5

Device Hub Client Updates

- All Categories

- Catalog

- Bill of Materials/Work Orders

- Import Bill of Materials

Import Bill of Materials

Shipstream allows users to import Bill of Materials from Excel or CSV files. This article explains the following topics: Bill of Materials Import Configs. Start Bill of Materials Import Task. Format…

Shipstream allows users to import Bill of Materials from Excel or CSV files. This article explains the following topics:

Bill of Materials Import Configs

Import Configs allow users to quickly run an import task based on pre-defined configurations for each merchant, or for all merchants. The standard Import Configs provided out of the box are available for all merchants and will cover most situations but if you need to add additional configurations follow the instructions below.

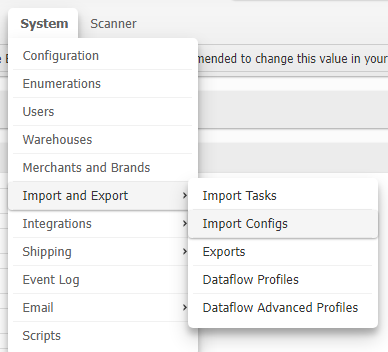

- Navigate to System > Import and Export > Import Configs.

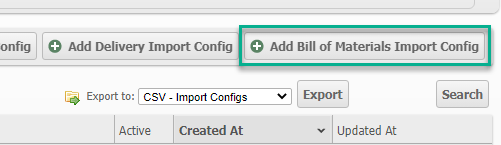

- From the "Import Configs" page, click Add Bill of Materials Import Config in right side of the Manage Import Configs header.

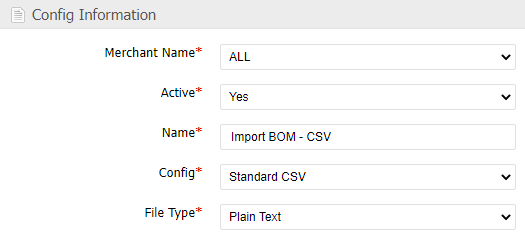

- In the Config Information, fill out the following fields:

- Choose a merchant to associate with this config, or use the default "ALL" value to apply to all merchants.

- Set the config's Active field to Yes.

- Set a descriptive Name for the Config.

- Choose the data format for your import files (JSON or CSV).

- Choose a file type for the import files (Excel or Plain Text).

- Click Save when finished updating the fields.

Start Bill of Materials Import Task

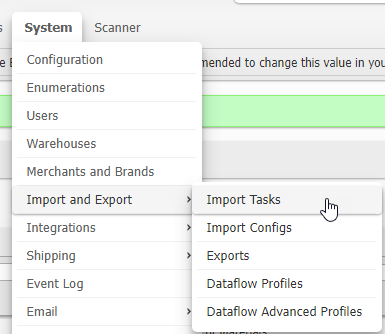

- Navigate to System > Import and Export > Import Tasks.

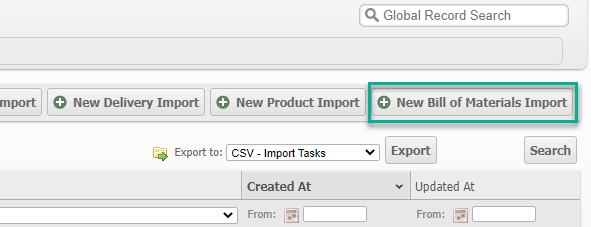

- Click New Bill of Materials Import.

- Select your Import Config from the list. If none appear in the grid, follow the instructions for creating a Bill of Materials Import Config.

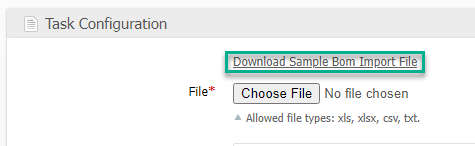

- Click Choose File to select your BOM import file. If you do not yet have a file, follow the instructions to Format the Import File.

- Choose the Merchant associated with the BOM products.

- Only one option for Handle Duplicates is currently supported. "Create", simply creates the BOM product regardless of if there is an existing BOM product.

- To receive an email notification when the BOM Import Task is complete, then set "Send Email on Complete" to yes. The BOM Import Task can take a moment when importing large product lists. This email address can be configured by navigating to System > Configuration > General > Import > Task Complete Email.

Import Products Troubleshooting

If your Import Task fails, there will likely be an error included on the task page. This can occur if a BOM component can not be found, or if there is a typo in the attribute names.

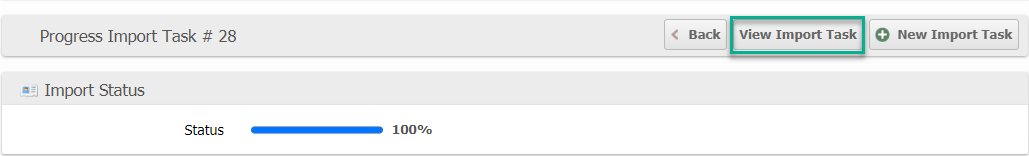

- From the Progress page, click View Import Task. Or if you are on the Import Task Grid, click the Import Task.

- Click the Records tab.

- The error message will appear in the Parse Error or Submit Error column. You can click this to view the specific error message.

Format the Import File

Once you've chosen a method for importing, you will file a download link for the sample import file on the next page or create one from scratch.

If you chose an Excel/CSV Import Task, then clicking this will download a .csv file

To better understand the attributes, please see the table below.

BOM Attributes

The following table contains examples and definitions for import file BOM attributes.

General

Attribute ID | Description | Example |

id | The "id" column is not stored but is required to associate multiple rows in the import file as belonging to the same record. All rows belonging to the same BOM must have the same id and the id must not be used to describe multiple BOMs in the same import file. | 1 |

name | The "Name" attribute. A descriptive, but not necessarily unique, identifier for the BOM product. *Required | Generic Parts Pack |

sku | The "SKU" attribute. A unique identifier for the resulting BOM product to be created or modified (if exists). | BOM-PARENT-001 |

yield_qty | Quantity produced after "Bill of Material" is performed. *Required | 2 |

is_kit_on_demand | Set this flag "yes" if items are picked when the order is fulfilled. This is done during the picking process. | yes |

is_kit_to_stock | Set this flag to "yes" if items are assembled, barcoded, and stocked on shelf. | yes |

assembly_instructions | Instructions displayed to the scanner user at the Work Order screen | Cover with plastic protection. |

priority | If multiple BOMs are defined for a SKU, then they will be processed in ascending order of this field. An integer. | 0 |

component_sku | The product SKU of the component. | component-A |

component_qty | The quantity of the component item consumed by the BOM. A positive integer. | 1 |

How did we do?

Work Orders

Virtual Inventory