Getting Started

Interface Basics

Printers and Scales

Shipping

Order Processing

Order Allocation

Order Processing Loop

Packing Solutions

Backorders

Ready to Ship

"Unable to Process" Order status

Address Validation and Classification

Packaging Features

Orders

Custom Fields for Orders

Reference Numbers

Other Shipping Options

Packing Instructions

Shipping Accounts

External Shipping Methods

Third Party Billing

Manifest Couriers

Packing Slip Design

Service Levels and Target Ship Dates

Outbound SSCC Barcodes

International Shipping

Tracking Numbers for Offline Shipments

Serial Number Tracking

Custom Fields for Shipments

Receiving

Catalog

Bill of Materials/Work Orders

Bill of Materials

Bill of Materials - Quantity-types

Work Orders

Import Bill of Materials

Virtual Inventory

Regulations

Products

Product Attributes

Lots/Expirations Tracking

Product Velocity

Import Products

Operations

Warehouse

Picking Classes

Picking Batches

Bulk Fulfill Orders

Put-Aways

Manifests (Loading)

License Plates

Time Tracking for Administrators

Time Tracking for Staff

Relocations

Import Locations, Lots and Inventory

Assets

Batching Presets

Rating

Rate Shopping

Rating Maps

Rate Groups and Plans

Fee Schedules and Adjustments

Virtual Shipping Methods

System

Configuration

Merchants and Brands

Warehouses

User Management

User Roles

User Groups

Login via Badge

Protected Customer Data

Enumerations

Technical Contact

Integrations

Shopify

Integrations Overview

Amazon Merchant Fulfillment

Amazon Selling Partner

CartRover

EasyPost

eHub

External Shipping Method API

Freight Club

Magento 1 / OpenMage

Merchant API Users and Roles

SPS Commerce

ShipStream Plugin Fostering Program

Webhooks

Global Integrations

Magento 2 / Adobe Commerce

WooCommerce

UPS

Scripting

Scripting Basics

Before Create Order Scripts

Before Create Order scripts Cookbook

Preprocess Packing Solution Scripts

Ready to Ship Time Scripts

Picking Class Shipment Matching Scripts

FAQ

How-To: FedEx Production Key Certification

How-To: Brand-Specific Shipping Account

Pattern and Replacement RegEx

ShipStream's Subprocessors

ISO Alpha-2 Country Codes

Printer Troubleshooting

ShipStream Flow

Release Notes

ShipStream Releases

Version 2025.7

Version 2025.6

Version 2025.5

Version 2025.4

Version 2025.3

Version 2025.2

Version 2025.1

Applicable Quantity Migration Guide

Version 2025.0

Revamped Delivery Processing

Version 2024.6

Version 2024.5

Version 2024.4

Version 2024.3

Version 2024.2

Version 2024.1

Version 2024.0

Version 2023.2

Version 2023.1

Version 2023.0

Package Tracking API Migration Guide (2023.0)

Version 2022.2

Version 2022.1

Version 2022.0

Version 2021.6

Version 2021.5

Version 2021.4

Version 2021.3

Version 2021.2

Version 2021.1

Version 2021.0

Version 2020.2

Version 2020.1

Version 2020.0

Version 2019.9

Version 2019.8.1

Version 2019.8

Version 2019.7

Version 2019.6

Version 2019.5

Device Hub Client Updates

Table of Contents

- All Categories

- Catalog

- Bill of Materials/Work Orders

- Virtual Inventory

Virtual Inventory

For products that are not physically stocked but are rather provided via "Kit On Demand" functionality, the issue of syncing available inventory for a "virtual" product to your shopping cart inventor…

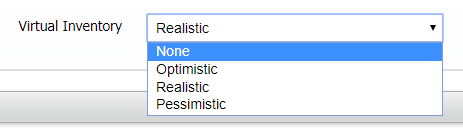

For products that are not physically stocked but are rather provided via "Kit On Demand" functionality, the issue of syncing available inventory for a "virtual" product to your shopping cart inventory can be resolved by setting the "Virtual Inventory" attribute. You have four options to choose from on a per-product basis: None, Optimistic, Realistic and Pessimistic.

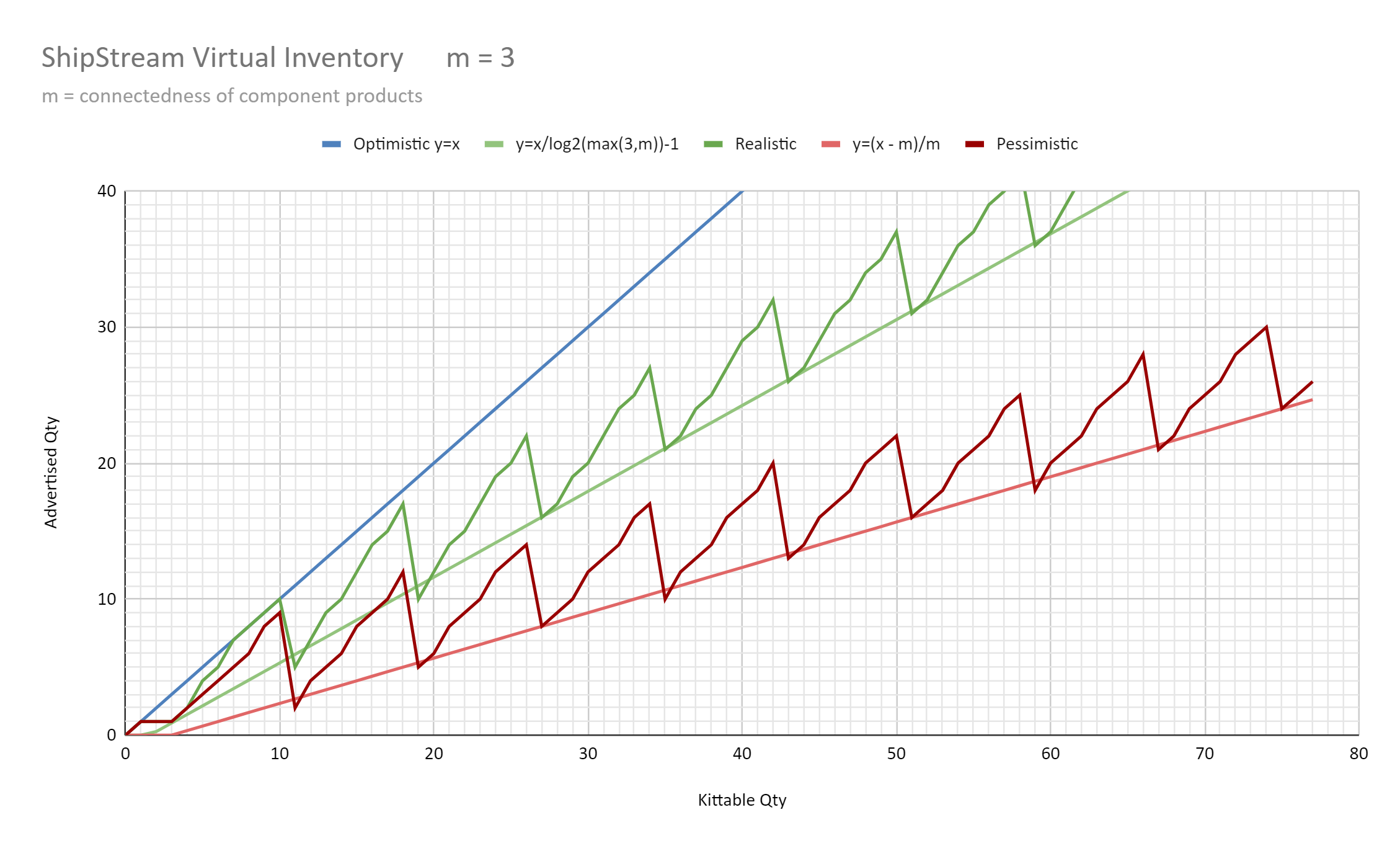

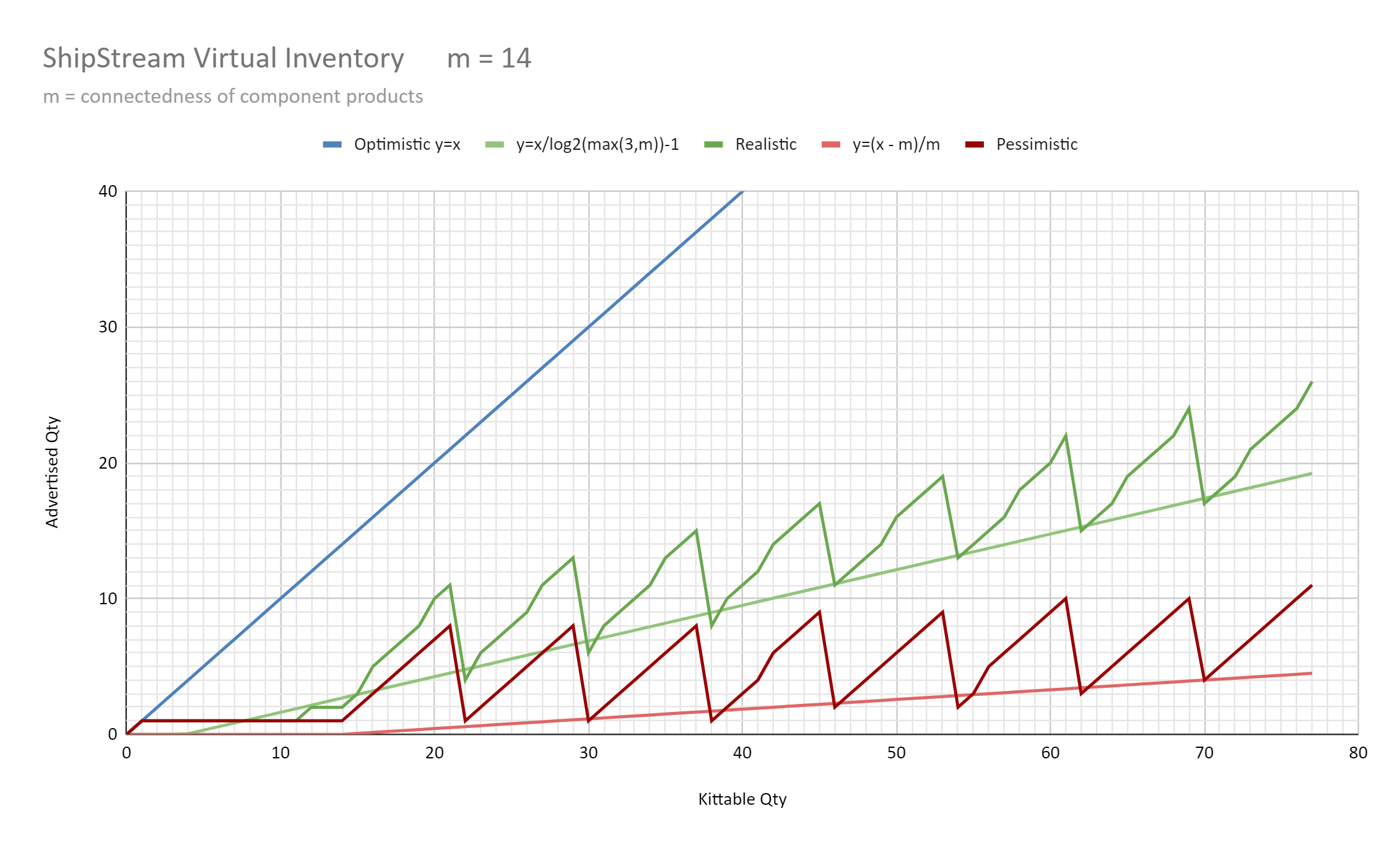

Virtual Inventory Formulas

When one or more of the components for a product built from a Bill of Material (BOM) is "shared" by multiple other products, advertising the maximum amount you could build for each product will over-state your inventory because those shared components would be represented in your overall inventory multiple times. The higher the degree of this "connectedness", the worse your overstatement of inventory becomes.

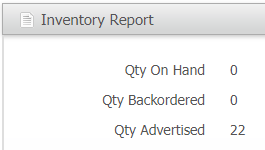

With the "Virtual Inventory" attribute you can inform the system how to apply your outlook on this conundrum. The formula you choose will be used to calculate the "Qty Advertised" for a given product and is automatically adjusted as inventory changes. The Qty Advertised will be computed both at the warehouse level and globally.

The formulas are described and compared below:

None

Only the currently stocked inventory for this product will be advertised. No Kit On Demand inventory will be included.

Optimistic

The maximum available amount that can be built from the available components. Does not consider a component's "connectedness".

Realistic

Depending on the most connected component in the BoM a reduced amount of inventory will be advertised.

Pessimistic

A more aggressive formula than Realistic, the advertised amount will be considerably lower than the Realistic formula. Use this value if you are very concerned about overselling or if your inventory sync is infrequent.

How did we do?

Import Bill of Materials