Getting Started

Interface Basics

Printers and Scales

Shipping

Order Processing

Order Allocation

Order Processing Loop

Packing Solutions

Backorders

Ready to Ship

"Unable to Process" Order status

Address Validation and Classification

Packaging Features

Orders

Custom Fields for Orders

Reference Numbers

Other Shipping Options

Packing Instructions

Shipping Accounts

External Shipping Methods

Third Party Billing

Manifest Couriers

Packing Slip Design

Service Levels and Target Ship Dates

Outbound SSCC Barcodes

International Shipping

Tracking Numbers for Offline Shipments

Serial Number Tracking

Custom Fields for Shipments

Receiving

Catalog

Bill of Materials/Work Orders

Bill of Materials

Bill of Materials - Quantity-types

Work Orders

Import Bill of Materials

Virtual Inventory

Regulations

Products

Product Attributes

Lots/Expirations Tracking

Product Velocity

Import Products

Operations

Warehouse

Picking Classes

Picking Batches

Bulk Fulfill Orders

Put-Aways

Manifests (Loading)

License Plates

Time Tracking for Administrators

Time Tracking for Staff

Relocations

Import Locations, Lots and Inventory

Assets

Batching Presets

Rating

Rate Shopping

Rating Maps

Rate Groups and Plans

Fee Schedules and Adjustments

Virtual Shipping Methods

System

Configuration

Merchants and Brands

Warehouses

User Management

User Roles

User Groups

Login via Badge

Protected Customer Data

Enumerations

Technical Contact

Integrations

Shopify

Integrations Overview

Amazon Merchant Fulfillment

Amazon Selling Partner

CartRover

EasyPost

eHub

External Shipping Method API

Freight Club

Magento 1 / OpenMage

Merchant API Users and Roles

SPS Commerce

ShipStream Plugin Fostering Program

Webhooks

Global Integrations

Magento 2 / Adobe Commerce

WooCommerce

UPS

Scripting

Scripting Basics

Before Create Order Scripts

Before Create Order scripts Cookbook

Preprocess Packing Solution Scripts

Ready to Ship Time Scripts

Picking Class Shipment Matching Scripts

FAQ

How-To: FedEx Production Key Certification

How-To: Brand-Specific Shipping Account

Pattern and Replacement RegEx

ShipStream's Subprocessors

ISO Alpha-2 Country Codes

Printer Troubleshooting

ShipStream Flow

Release Notes

ShipStream Releases

Version 2025.7

Version 2025.6

Version 2025.5

Version 2025.4

Version 2025.3

Version 2025.2

Version 2025.1

Applicable Quantity Migration Guide

Version 2025.0

Revamped Delivery Processing

Version 2024.6

Version 2024.5

Version 2024.4

Version 2024.3

Version 2024.2

Version 2024.1

Version 2024.0

Version 2023.2

Version 2023.1

Version 2023.0

Package Tracking API Migration Guide (2023.0)

Version 2022.2

Version 2022.1

Version 2022.0

Version 2021.6

Version 2021.5

Version 2021.4

Version 2021.3

Version 2021.2

Version 2021.1

Version 2021.0

Version 2020.2

Version 2020.1

Version 2020.0

Version 2019.9

Version 2019.8.1

Version 2019.8

Version 2019.7

Version 2019.6

Version 2019.5

Device Hub Client Updates

Table of Contents

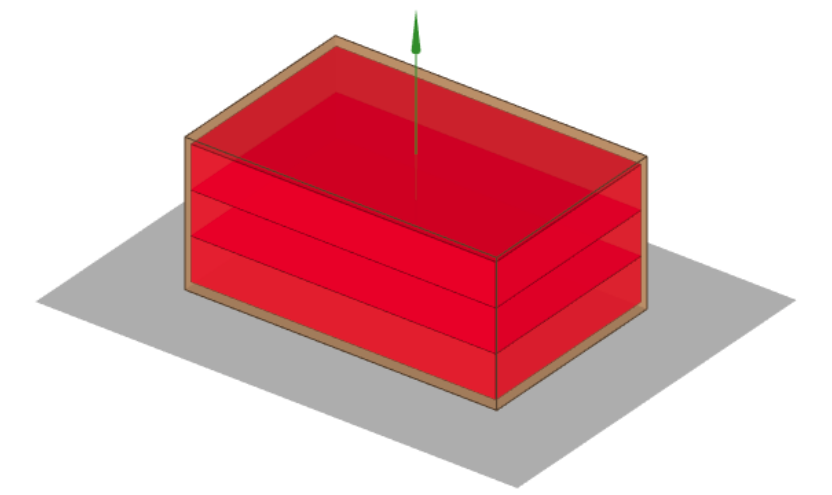

Infill

ShipStream's Packing Solutions providers use "Infill" to account for the space you may want to leave inside a container to protect the contents, such as air pillows, packing peanuts, crumpled paper,…

ShipStream's Packing Solutions providers use "Infill" to account for the space you may want to leave inside a container to protect the contents, such as air pillows, packing peanuts, crumpled paper, etc.

In this example you can see that the container has 0.25" of space between the product and the insides of the container and 0.5" of space above and below the products.

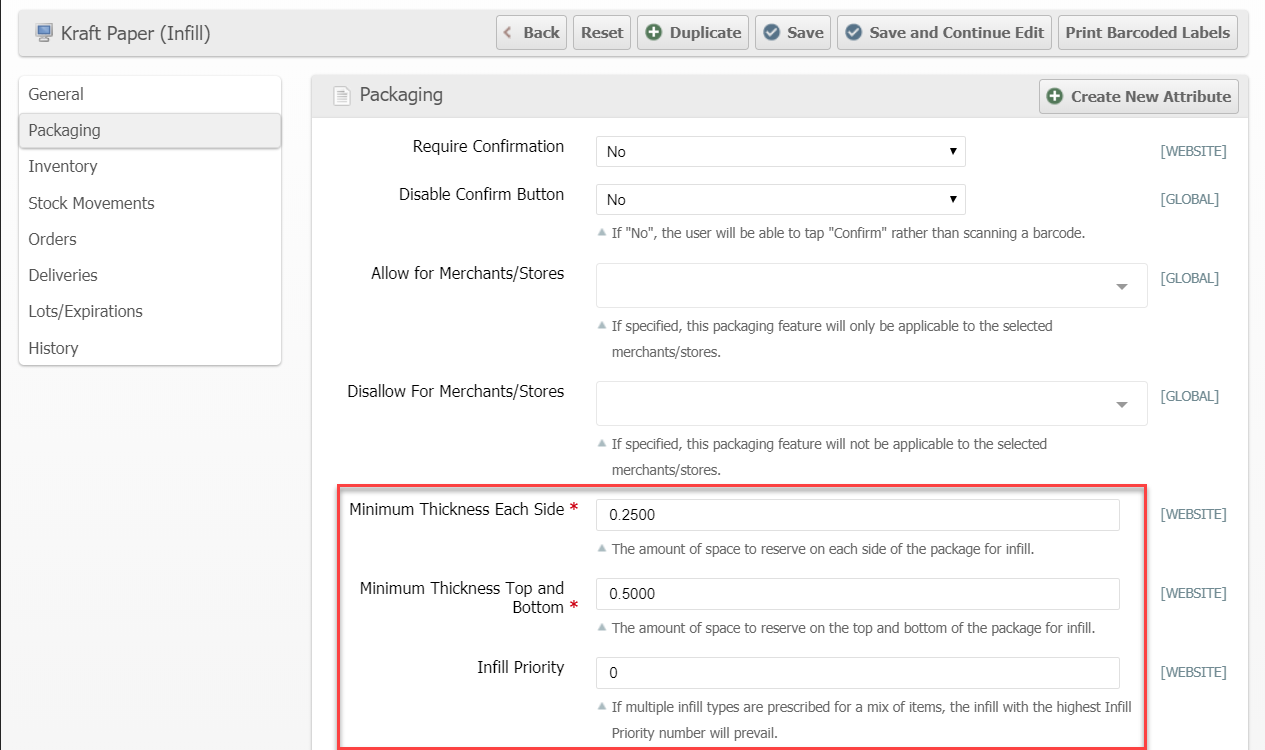

If you want to account for Infill in your Packing Solutions, start by creating an "Infill" type Packaging Feature. You can create as many Infill variants as you need.

When multiple items on the same order resolve to different Infills they will be sorted by the Infill Priority and the one with the Lowest number will be chosen.

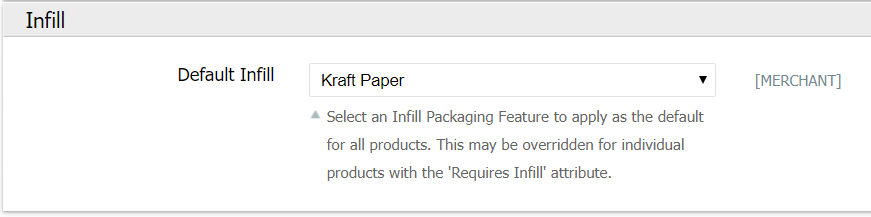

Default Infill

You can set a Default Infill in the System > Configuration > General > Packing Solutions > Infill section.

This will determine the default Infill that will apply to all products. You can set different values at the Merchant scope to have different defaults for different merchants.

The default value may be overridden at the product level as described below or also via a Preprocess Packing Solution Script.

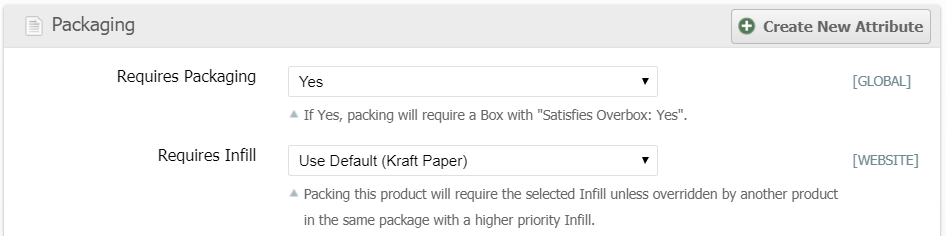

Product Infill

The "Requires Infill" product attribute allows you to override the default with values "None" to disable Infill for that product or any of the available Infills that exist in the current scope.

How did we do?

Containers